|

|

Coir Processing – Technology and Machinery

|

| Introduction | Fiber Extraction | Green Decortication | Formation of Yarn | Rope making | Dyeing | Printing | Designing |

|

Formation of Yarn

|

|

| Hand Spinning |

| The usual practice in hand spinning is to roll the fibre into short length of 6 to 9 inches, giving a clock-wise twist by hands. When a sufficient quantity has been made, two of these short lengths are taken in hand together and made into yarn of two plies by giving a counter twist, using both palms. When the counter twist reaches near the end of the striking, further pieces of short lengths kept ready are added one after other, while the counter twist by hand is continued till the required length of yarn for a knot is reached. This is reeled in the form of a hank and a knot is made at the end. Handspun yarn always has a soft twist. |

| Traditional Ratt Spinning |

| Spinning is usually done on the ‘Charka’ or spinning wheel. Wheel spinning is gradually displacing hand spinning. From the middle of the 19th century, coir spinning wheels have been introduced with a view to increasing production and obtaining the hard twist required for the manufacture of matting, etc. To prepare two-ply coir yarn on the spinning wheel, one set of two wheels, one stationary and the other movable is required. The stationary wheel usually contains two spindles set in motion through the centre of the wheel. The movable wheel contains one spindle only. Two persons take the silvers of ‘coir’ prepared and kept ready after willowing. Usually women keeps them in their arm pits, make a loop with a small quantity of fibre and then puts the loop thus formed into the notch of one of the spindles on the stationary wheel and gives the fibre a uniform thickness while walking backward. Another operator then gives the twist to the fibre thus led by turning the handle of the spinning wheel. This operation is continued till the required length of strand is reached. The strands are then passed through a grooved rod and tied together into the notch of the spindle, the grooved rod being allowed to move forward. The movable wheel is turned in the opposite direction. The object of the grooved rod is to regulate the twist of the yarn and to prevent entanglement of the strands at the time of doubling. When the grooved rod reaches the stationary wheel, the turning of the spindles of the spinning wheel is stopped and all the ends from that of the stationary wheel are cut off and the yarn is tested to see whether there is sufficient twist. If more twist is required, the movable wheel is turned toward its original direction till the required twist is obtained, if it contains more twist than desired, the movable wheel is turned in a direction contrary to the original twist. Traditional Wheel spinning using a spinning wheel requires three people, who may produce 12-15 kg of yarn per day. |

| Motorised Traditional Ratt |

| Motorised Traditional Ratt is a developed form of a coir spinning ‘charka’. Here, the stationary ratt is rotated using a suitable contrivance attached to an electric motor. By attaching the rotating system to the stationary ratt one worker is avoided and the productivity is increased. The wages thus earned are divided among the two workers resulting in enhancement of wages of spinners. This system has been introduced recently and found successful in the industry for spinning all varieties of yarn. |

|

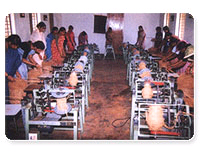

Motorised Ratt

|

| The research and development in coir industry was mainly aimed for reducing the drudgery of the workers involved in the spinning of coir yarn on traditional and motorised traditional ratts. Two or three spinners are engaged for exercising the production activity in yarn spinning, where they are exposed to changing weather conditions, which ultimately affects the production. They are also forced to walk up and down in the spinning yard for taking the individual strands and for doubling operation. It was a long time dream of the coir industry to introduce a contrivance for reducing the drudgery of the labourer and improve the productivity and also enhance the earnings of the workers engaged in the spinning. As a result of research and development, a spinning device for attaining the real goals of reducing the drudgery, improving the productivity and to improve the working environment, the motorised ratt was introduced in the industry. In the case of a motorised ratt the spinner is made to sit on a chair /stool and roll the well cleaned fibre stacked in the spinning trays attached to the spinning device where the yarn is spun and wound over the bobbins attached to the ratt. The simple device is now popular in the industry and the benefit of the device has been extended to all spinning areas, all over India. Coir board has taken all efforts to popularise this spinning device and a scheme has been evolved under ‘Mahila Coir Yojana Scheme’ for providing motorised ratt to spinners at a subsidised rate. The introduction of the motorised ratt in the industry has paved way for increasing the employment opportunity, as the new generation has taken up the spinning activity in the coir sector as the change in the working environment. All varieties of coir yarn in the industry are produced on ratt with a slight alteration on the equipment. |

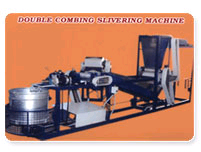

| Automatic Spinning |

| The production turnover in the case of hand spinning was less. The efforts to maximise the productivity of the yarn resulted in the introduction of automatic spinning machine units. The automatic spinning machine units are capable of production of yarns of runnage varying from 50 to 300 meters/kg and twists from 10 to 30 twists/feet. Coir fibre in the form of bales is the raw material for the unit. These fibres are soaked in water for one hour and are cleaned in the willowing machine. Pith content and the hard bits are removed in the process. Manual attention is also required to remove the hard bits to the fullest extent. These cleaned fibers are passed in to the feeder of silvering machine where the fibers are paralleled and drawn by draw rollers. These paralleled fibers are twisted and taken on to drum.The twisted paralleled fibers are called silvers. These silvers are fed on to the feeder of the spinning machine and are combed and to made to fall on to “W” tray. Core threads of nylon/cotton/HDPE/LDPEassing in the tray are used as carrier agent for the coir fibres. These fibres are entwined on to the thread and are twisted by the grip nozzles/rollers. Two such strands are doubled and wounded on to a bobbin to form the yarn of required twist and runnage. The automatic spinning machine facilitates spinning of any varieties of yarn according to the requirement of the industry by varying the parameters of the machine to vary the twist and/or runnage. The yarns thus formed are wound in the form of balls for the easy transportation. |

|